Painstaking Lessons Of Info About How To Check Main Bearings

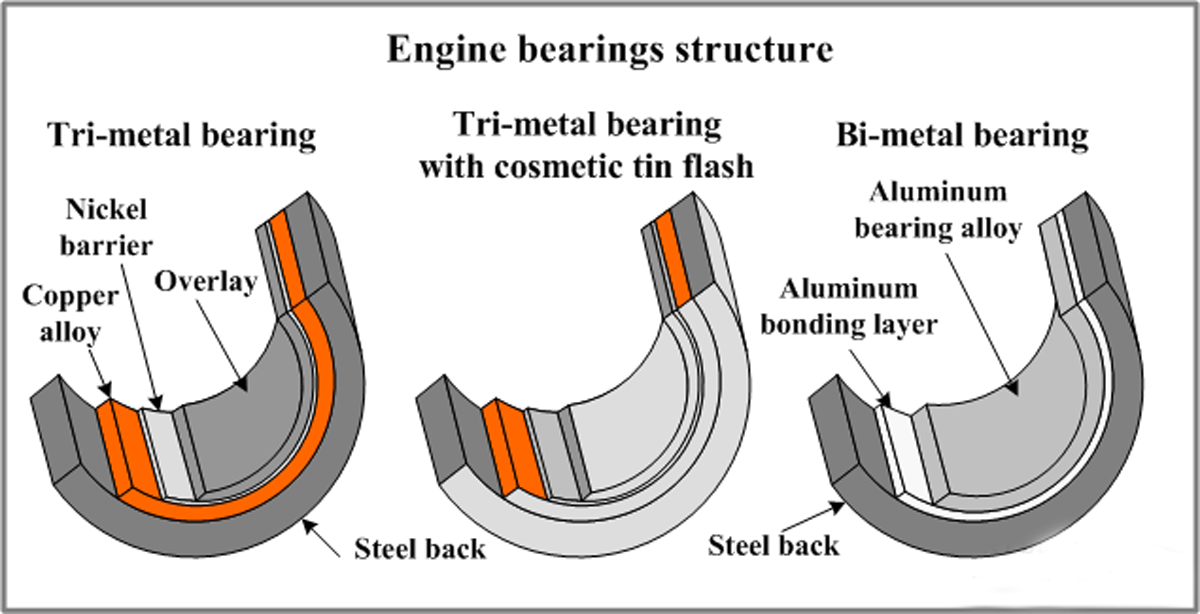

Load capacity (fatigue strength) is the maximum value of cycling stress that the bearing can withstand without.

How to check main bearings. Separable bearings such as tapered roller bearings may be checked by individually examining their rolling elements and the outer ring raceway. Remove the rear brake drums and inspect the axle for leaking oil. Question title * please choose an appropriate title for the question so it can be answered easily.

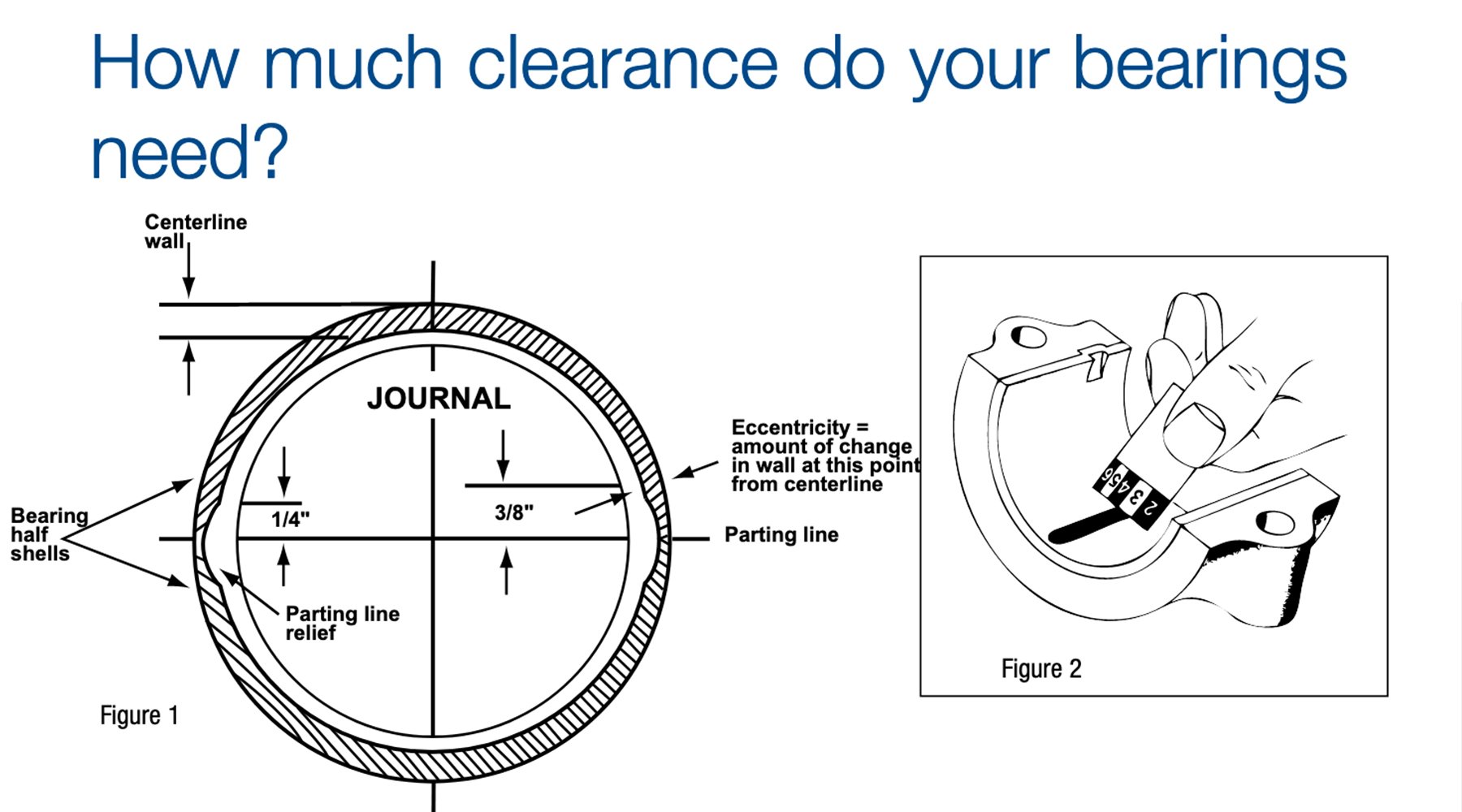

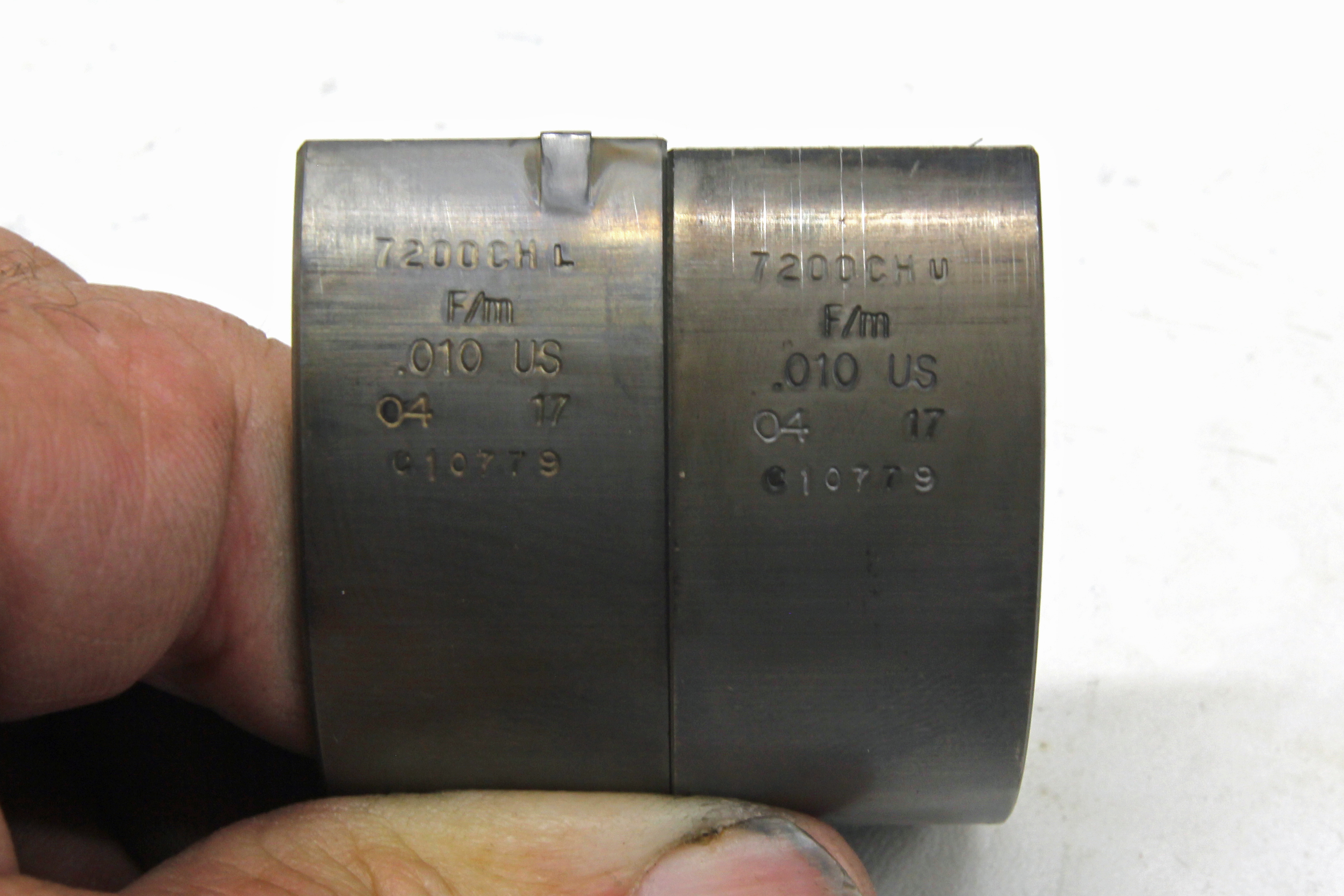

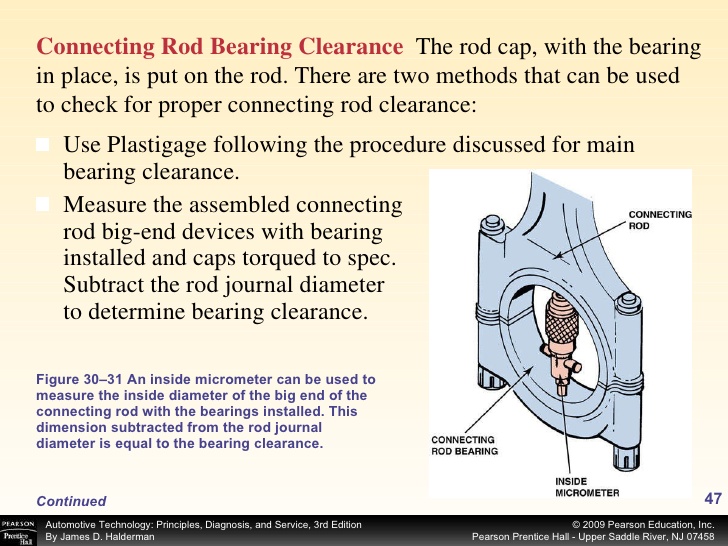

How to check bearing clearances measuring bearing clearance is one of those steps that all good engine builders take to establish a solid and reliable. Username * please type your username. Subtract the thickness of the drill bit (measure, don’t assume), and you will have the thickness of the.

Forcefully spin the wheels on the elevated side of the camper with your hand. Place the drill bit on the inside curve, and then measure the bearing. As a final check, lubricate the bearings and the crank, put the crank in the block, torque down the caps and spin the crank.

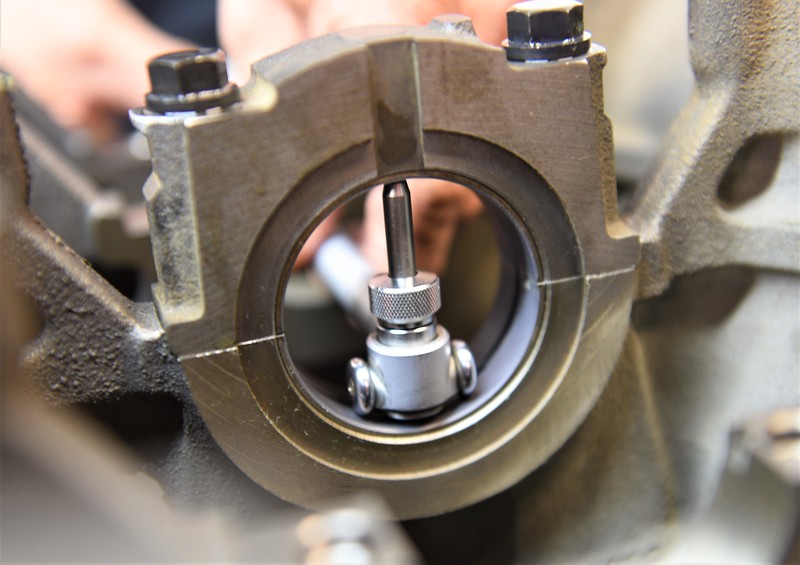

This is how to check your bearing clearance with a very inexpensive product called plastigauge. Move the axle hub from side to side to check for play. Using an outside micrometer, carefully measure the crankshaft’s main journal diameters and record the measurements.

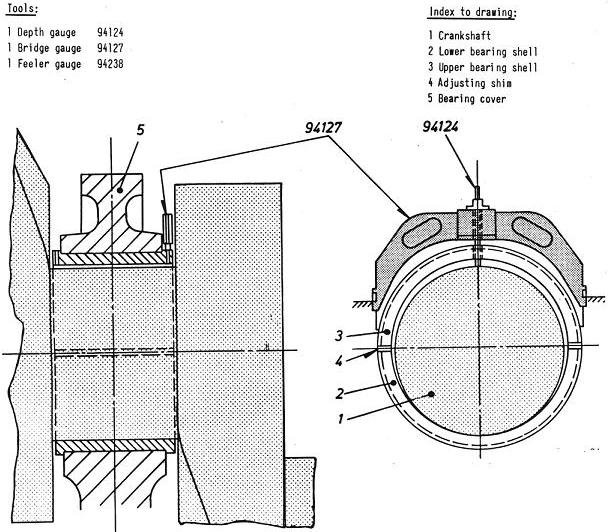

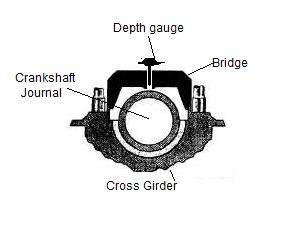

Setting bearing clearance for a performance engine is a fundamental step in the building process. Second, remove the oil pan and oil pump if necessary to inspect the main bearings. The main properties engine bearings must posses:

Set up a bore gauge to this. Large bearings cannot be rotated manually;. There are no quick and easy ways to establish this critical.