Unbelievable Tips About How To Check Runout

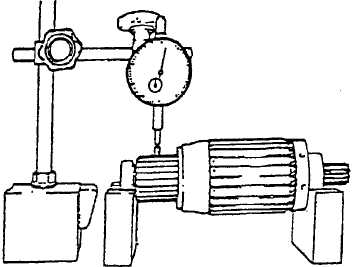

Place the dial indicator needle against the rotor.

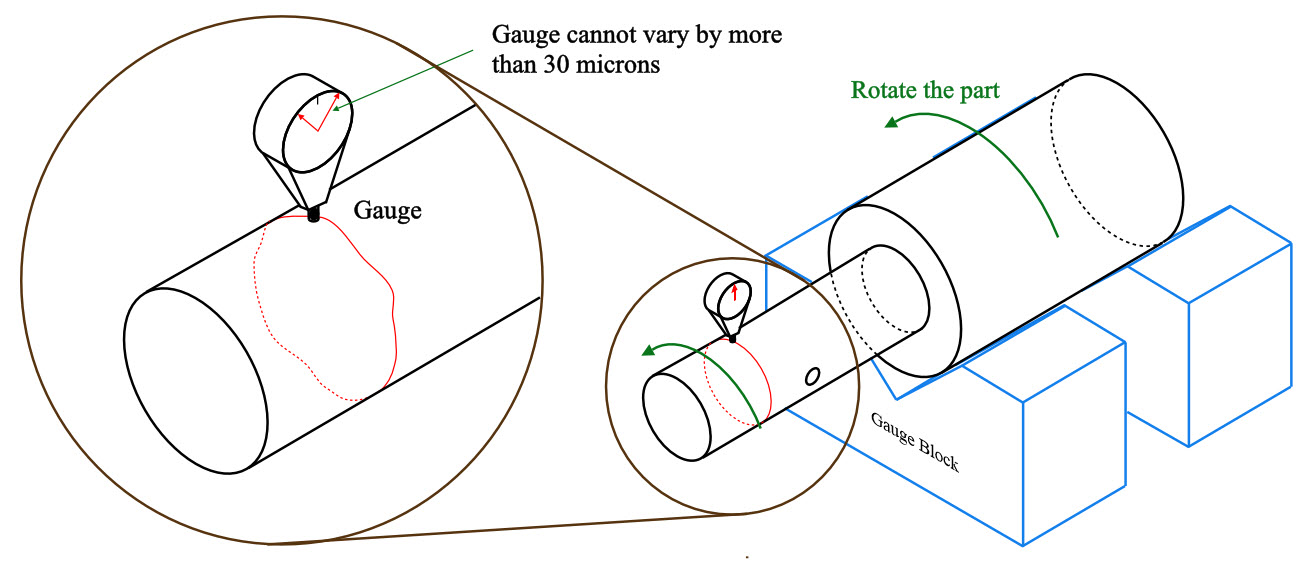

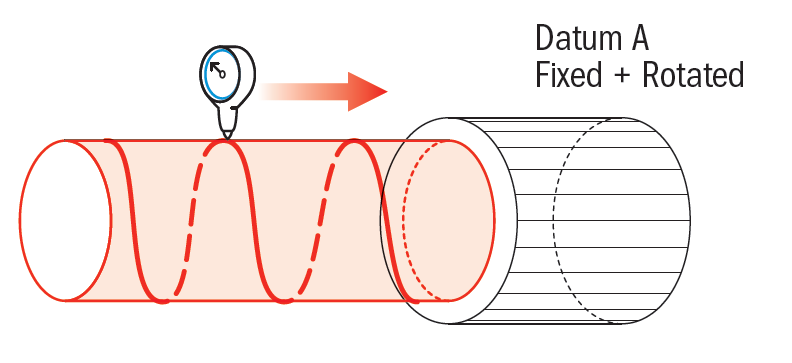

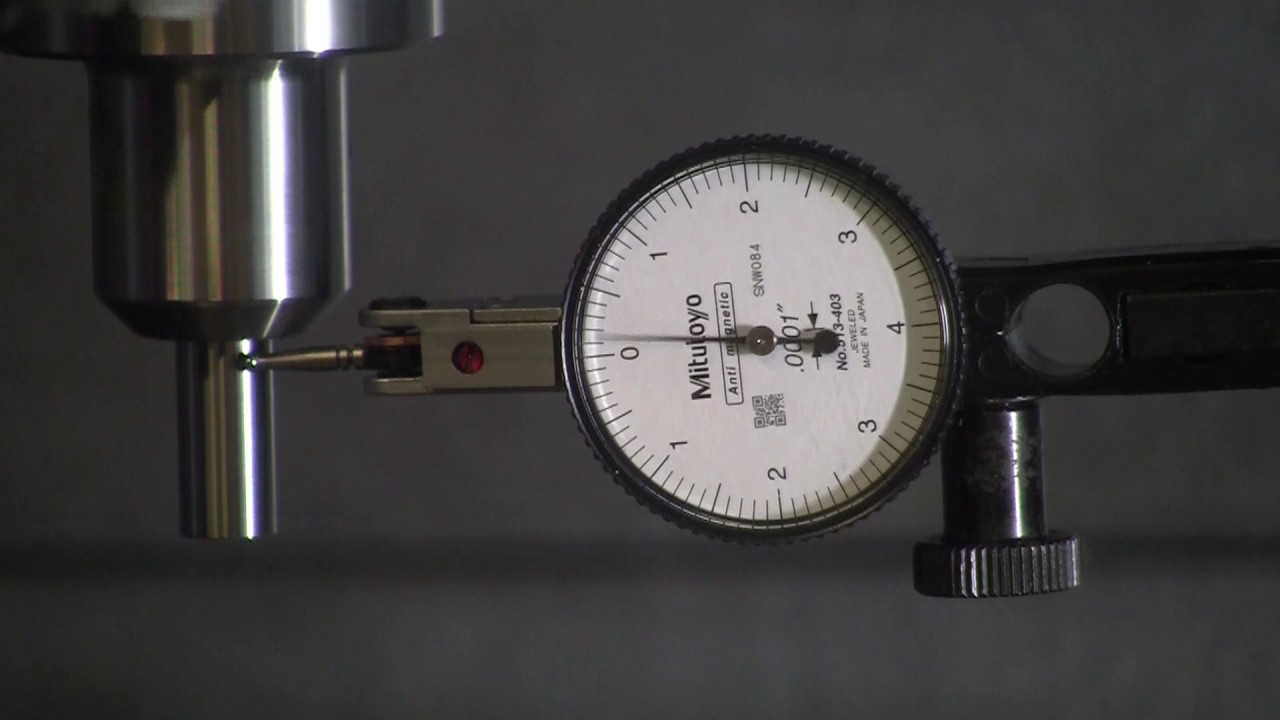

How to check runout. I would suggest using a chuck (divider head) to contact the datum and then use a dial indicator (not digital) on a stand to. To check runout, you’ll need a dial indicator (here’s a link to the dial indicator i use)with a magnetic base. The maximum you want on most vehicles is.003 th.

How to check for brake rotor runout tools and materials. The pin of a dial gauge is then set on the. How to check for runout.

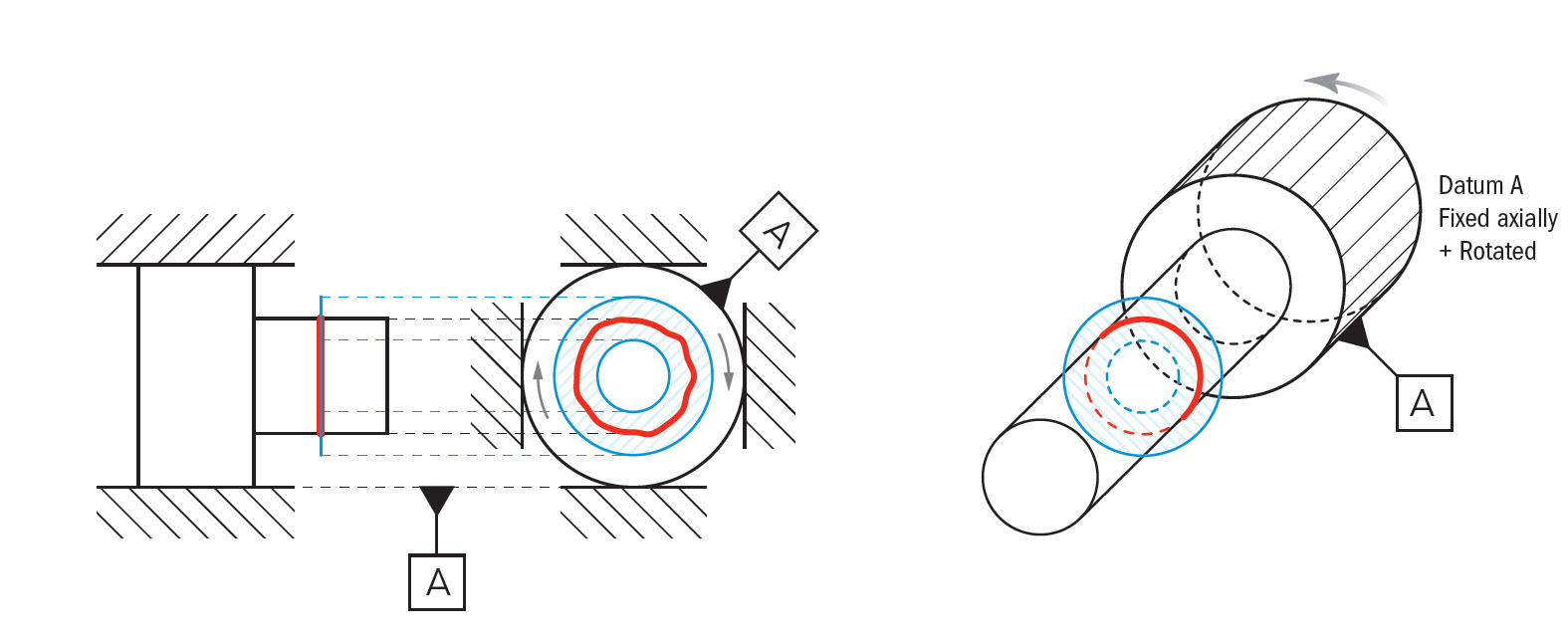

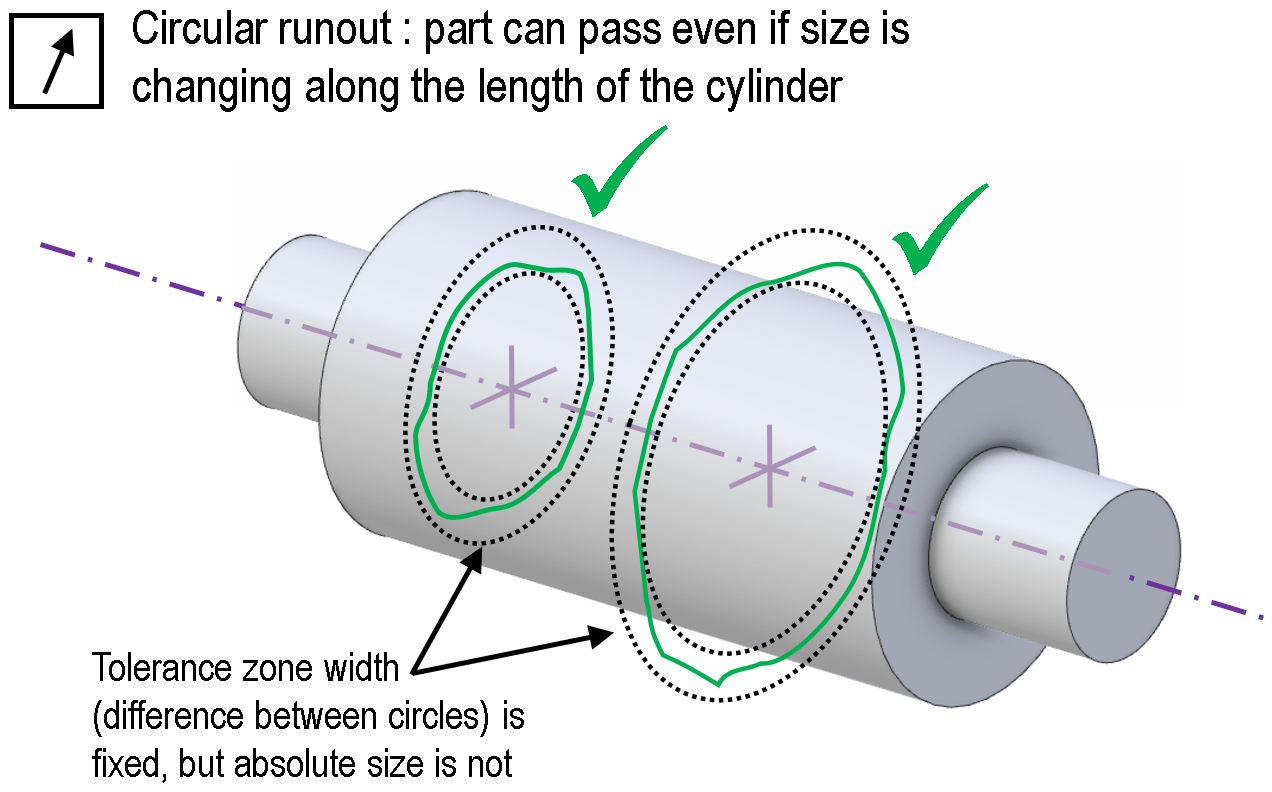

This can cause mild to excessive vibrations depend. In machining, runout refers to inaccuracies in a tool or piece of equipment that cause it to spin off its ideal axis. Next, use the jack to move the vehicle off the.

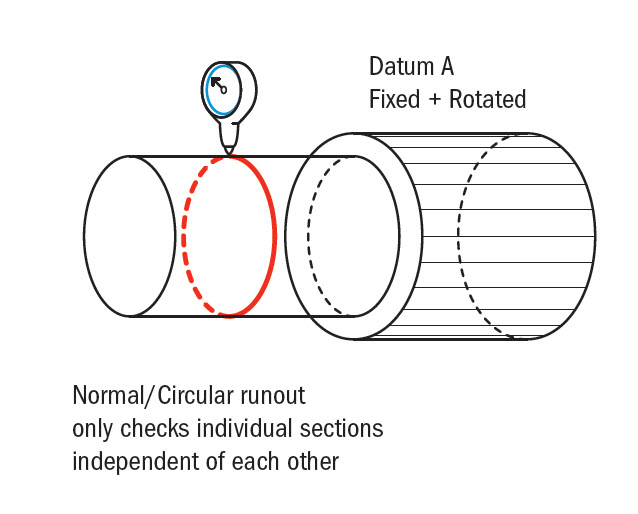

One common method is to use a dial indicator. The indicator is placed on the chuck, and the spindle is. Tir, fim, total runout, and ci.

To check the lateral runout on a conventional flywheel, place the tip of the dial indicator on the flywheel's surface, and rotate it with a turning tool or turn the crankshaft bolt with a socket and. The list of best recommendations for how to check bellhousing runout searching is aggregated in this page for your reference before renting an apartment. How to measure a rotor runout remove the brake pedal and floor board.

Align the zero mark on the adjustable bezel with the lowest spot on the brake rotor. This video shows you how to move the rotor position on the hub to change the rotor runout. Rotate the rotor 360 degrees and notice the highest runout value.